Expanding youth employment in Zimbabwe through vocational skills training

Go back

$2,730

This is a project to equip Chipinge College of Horticulture in Zimbabwe with new machinery, tools, and materials across eight vocational training departments.

It is directly benefiting 130 youth from disadvantaged backgrounds by strengthening hands-on learning and improving their chances of employment or entrepreneurship after graduation.

- Region 🇿🇼 Zimbabwe

- Sector Education

- Beneficiaries 130

- Stage Pilot

Since 1995, Chipinge College of Horticulture has quietly trained young people in practical trades, from motor mechanics to cosmetology, often with limited resources and minimal funding.

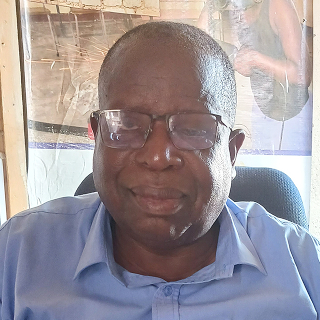

Administrator Victor Ngwenya and his dedicated team of ten staff continue to witness the transformative power of opportunity. Many of their students come from child-headed households or families struggling to survive on very low incomes. Most can barely afford the modest $150 per semester in fees, which the college relies on to pay tutors and purchase materials.

Despite these challenges, the college has remained a cornerstone of practical education in the community. Graduates have launched small businesses, found work in the construction and beauty industries, and become role models to their peers.

Why this matters

Zimbabwe’s youth unemployment rate remains one of the highest in Africa. In communities like Chipinge, many young people leave school without clear career pathways, leaving them vulnerable to drug abuse, early pregnancy, and exploitative work.

Vocational training provides a crucial bridge to opportunity, but only when it is practical, well-equipped, and relevant. Limited government support and widespread poverty have long constrained the potential of institutions like Chipinge College.

What the project will change

This project will upgrade the college's ability to deliver hands-on vocational training to their 130 students. With new sewing machines, welding kits, computer equipment, and beauty tools, students will no longer have to share outdated or broken equipment during their training.

Technical stuff

The Details

- Equipment procured 0

Updates

From the field

Departmental workshops begin at Chipinge College with new machinery for students

Posted 14 Jan 2026

We resumed lessons on 7 January 2026, with departments fully engaged in hands-on classes. The new tools and materials provided by Kwanda are already in use across various workshops. Several departments have shared videos showcasing this progress.

Resumed first semester lessons on 7 January 2026

Conducted one-day departmental workshops

Delivered departmental trainings on machinery and tool usage

Provided detailed tutor-led instruction on equipment handling

Shared training progress videos across departmental platforms

We are now focused on sourcing additional tools and materials to expand training access and improve outcomes for more students.

I greatly appreciate the donation from your organisation. It has motivated us students and improved the standard of our training.

New tools delivered to 8 training departments at Chipinge Vocational College in Zimbabwe

Posted 11 Dec 2025

This update shares progress on strengthening practical training at our vocational centre, thanks to generous support from Kwanda.

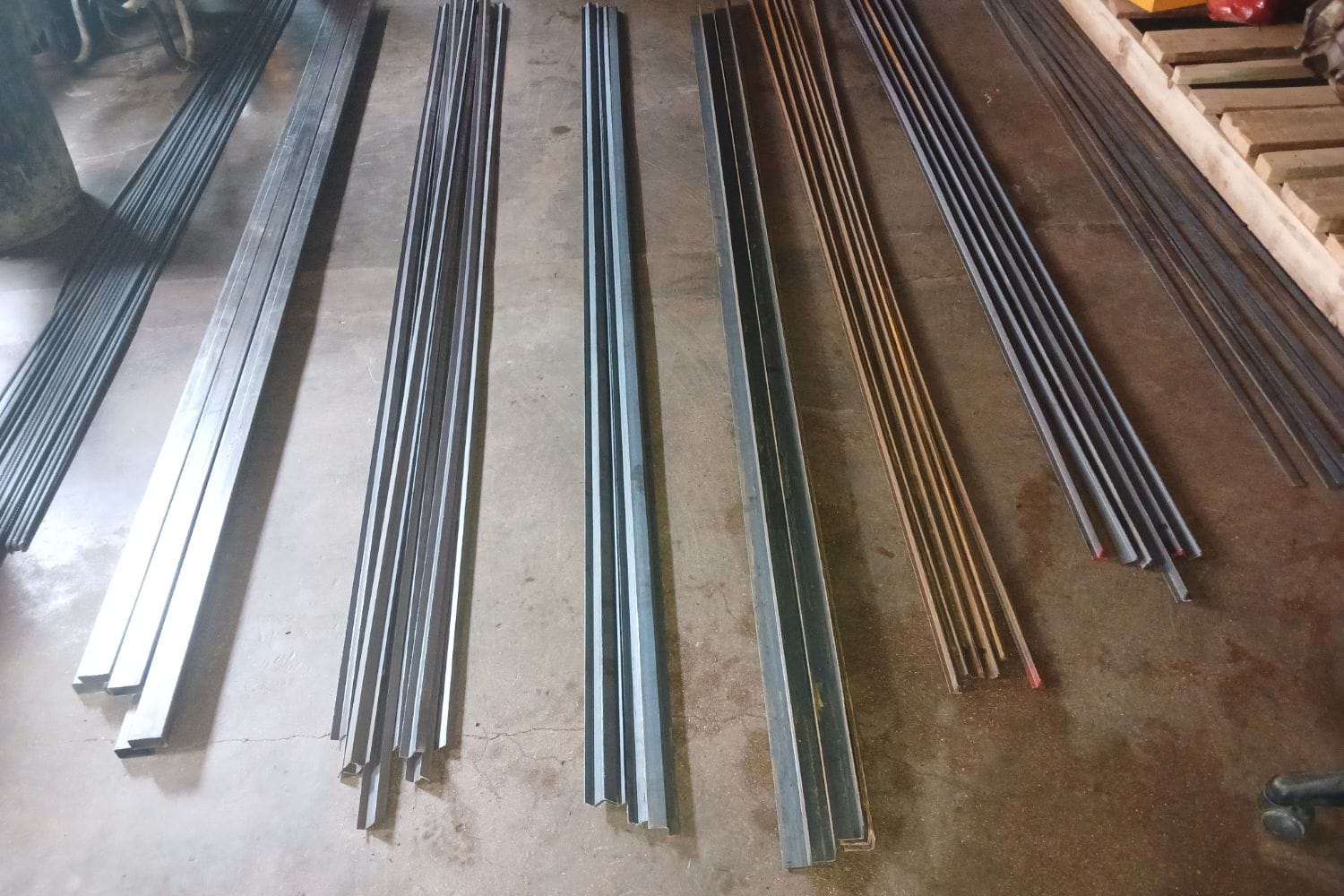

We were able to purchase and deliver new tools and materials to eight departments: Cosmetology, Garment Making, Welding, Motor Vehicle Mechanics, Carpentry and Joinery, Brick and Block Laying, Plumbing and Drain Laying, and Computers. Everything has been registered and safely stored in our main storeroom, ready for use.

Activities:

Registered new equipment in each department’s control log

Added all items to the central assets register

Stored tools and materials securely in the main storeroom

Introduced students to the new equipment through tutor-led training

Held hands-on practice sessions in class

Shared updates with staff and students on current stock and remaining needs

We’re now exploring options for further support so that every student can train with the tools they need.

Eight Chipinge College departments equipped with vocational training tools

Posted 27 Nov 2025

We held a three-hour planning meeting with tutors and management to identify what each department needed. Each department submitted a priority list, and the college collected three quotations for every item before purchasing.

Convened a three-hour planning meeting with tutors and management

Reviewed equipment and material needs across eight departments

Agreed minimum practical training requirements and departmental budgets

Requested and reviewed three quotations for each item

Procured tools and consumable materials for eight vocational areas

Distributed equipment to departments for immediate use in lessons

Zvobgo Doreen a student in the cosmetology department said:

I am happy with the new equipment and materials we received as a department which will improve our training in practical work.

We will assess how the equipment is being used after the current semester ends in March 2026, gathering feedback from tutors and students to inform any additional procurement needs.